Services

AFC offers support that’s as reliable and effective as our products. Whether you’re looking for project estimates, fabrication details, or technical support, help is just a click away.

Inspiration

See the world of possibilities that our high-quality fiber cement panels can add to any structure. Review our previous work to find inspiration for your project.

About

For over 30 years, we have been proudly supplying our customers with the best high-density fiber cement products on the market.

Resources

We’re here to provide the information and support you need to make the most of your AFC products. Browse our resources to find the answers to your pressing questions.

FAQs

General

- Fabrication: We offer state-of-the art fabrication which consists of cutting, drilling, and sealing panel edges.

- Shop Drawings: We offer shop drawings. When combined with fabrication, we make the installation process significantly quicker and more efficient.

- Engineering: Fully stamped engineering calculations can easily be added to any job for the panels and attachment system.

- Estimating: We utilize takeoff software to run estimations for each project. This provides accurate and itemized quotations.

- Technical Support: We provide technical support at every stage of the job. From detailing the process to installation, we review all details and layouts; provide installer support and make site visits.

AFC offers warranties on all products ranging from 10 to 20 years. Contact house@afccladding.com for more warranty information.

Products

Maintenance is not required. Periodic cleaning might be depending on the area. For cleaning specifics, see AFC’s Maintenance, Fabrication and Storage Guidelines.

All AFC products have passed ASTM E136 (Non-combustibility). Most products are IAPMO certified including passing ASTM E84 (Surface Burning Characteristics) and are ASTM C1186/1186 Type A Grave IV fiber cement flat sheets. Contact house@afccladding.com for more information.

Materials & Resources

MRc1 Option 2 – Building Life-cycle Impact Reduction (1-4 points)

MRc2 Option 1 – Environmental Product Declarations (1 point)

MRc4 Option 1 – Material Ingredients (1 point)

Energy and Atmosphere

EAc2 Option 1 – Optimize Energy Performance (1-20 points)

Indoor Environmental Quality

EQc5 Option 1 or 2– Thermal Comfort (1 point)

A majority of AFC’s products show excellent UV resistance in real world applications and UV testing. Patina, Patina Inline, and Patina Rough will fade and model over time, mainly in the darker colors. Contact house@afccladding.com for more warranty information.

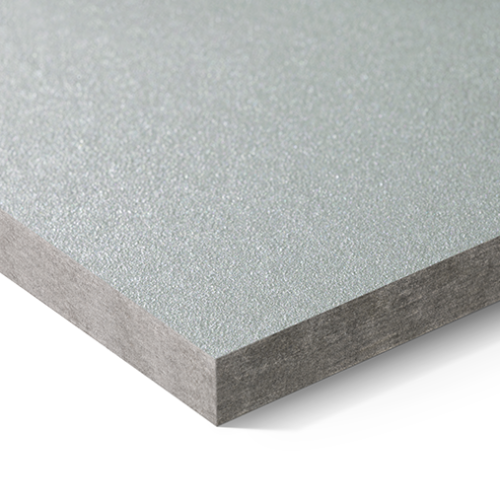

Swisspearl Avera: Integrally colored with a transparent top layer.

Swisspearl Carat: Integrally colored with a translucent, lightly pigmented top layer.

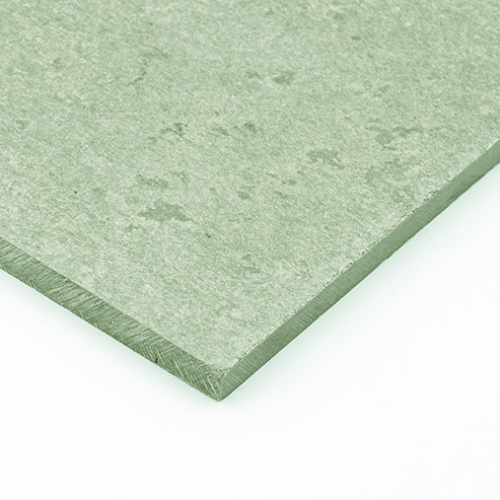

Swisspearl Nobilis: Grey based with a translucent, lightly pigmented top layer.

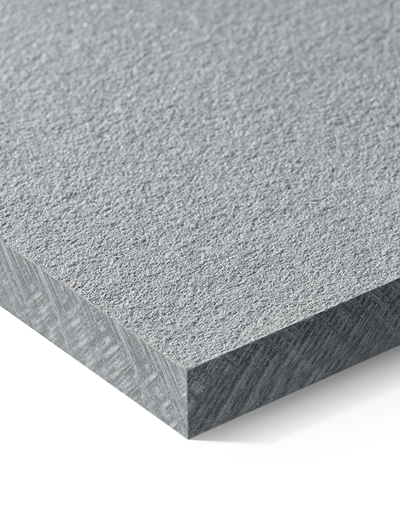

Swisspearl Patina NXT: Through-colored with a sanding grain line and a clear water repellent hydrophobic coating.

Swisspearl Patina Inline NXT: Through-colored with a sanding grain line, a clear water repellent hydrophobic coating and milled grooves.

Swisspearl Patina Rough NXT: Through-colored with a sandblasted surface texture and a clear water repellent hydrophobic coating.

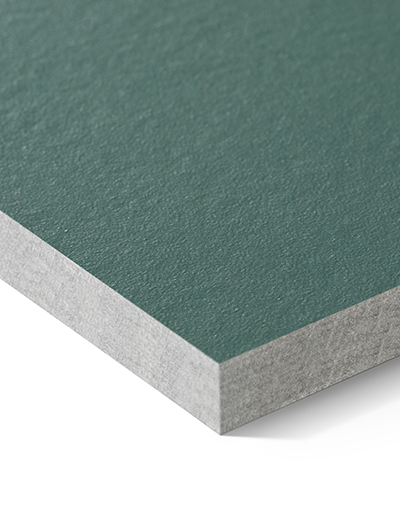

Swisspearl Planea: Grey based with an opaque top layer.

Swisspearl Reflex: Integrally colored with an iridescent top layer.

Swisspearl Terra: Grey based with a translucent, strongly pigmented top layer.

Swisspearl Zenor: Base panel resembles the surface coating with an opaque top layer.

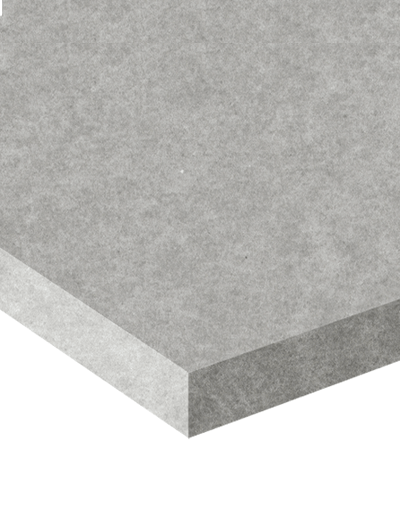

Swisspearl Construction: Raw (unpigmented) core with no surface coating. For use as a facade product, we recommend fully sealing or painting this product.

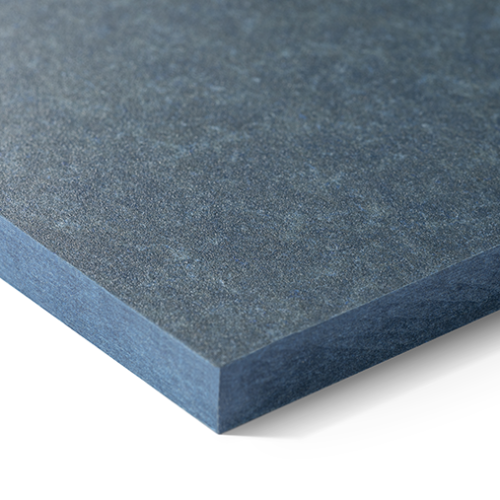

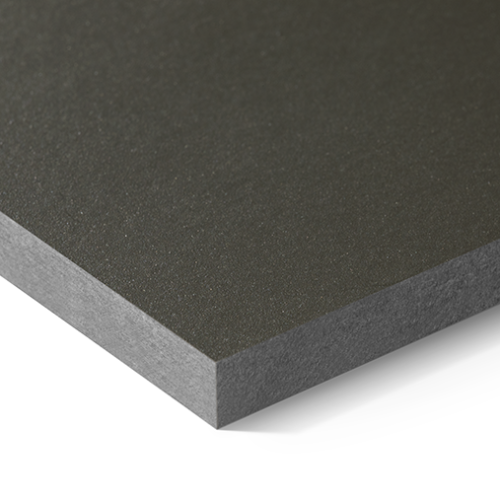

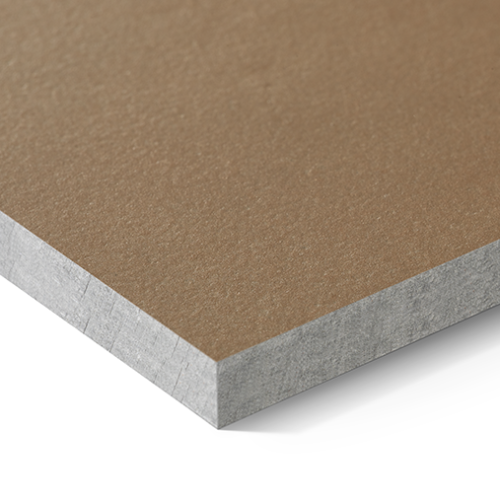

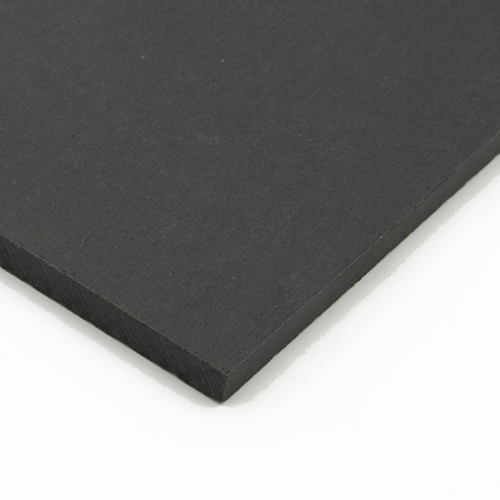

AFC Carbon Stone+: Through-colored dark fiber cement with a light sanding grain and a transparent UV protective coating for reduced fading.

AFC Carbon Lines+: Through-colored dark fiber cement with routed linear grooves and a transparent, UV protective coating for reduced fading.

AFC Carbon Groove+: Through-colored dark fiber cement with a transparent, UV protective coating for reduced fading.

AFC Carbon Reflect+: Through-colored dark fiber cement with a transparent UV protective coating for reduced fading.

AFC Lines+: Through-colored core with routed linear grooves and a transparent, UV protective coating for reduced fading.

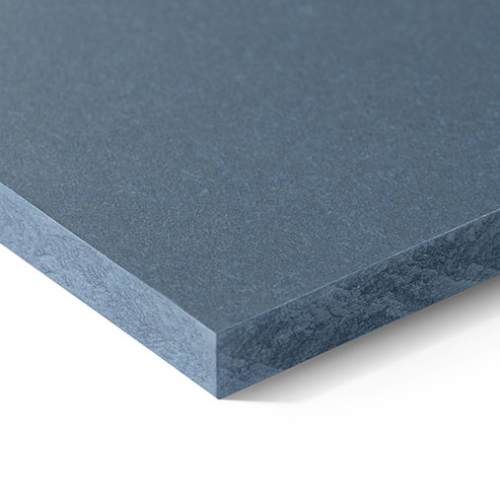

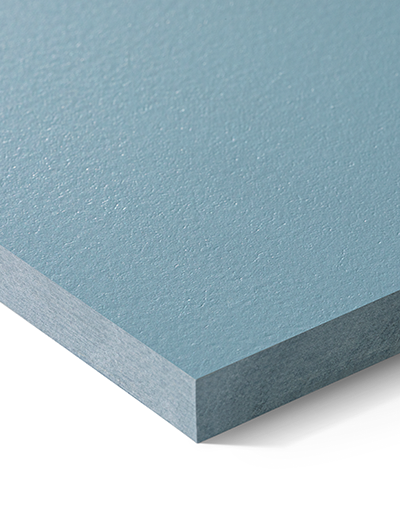

AFC Sky: Through-colored core with a cloudy, natural surface appearance. (Some fading and additional modeling will occur.)

Installation

If possible, panels should be stored in a dry ventilated space. If storage is outdoors, panels must be covered with a tarp that has ventilation on all sides of the panels, in a tent like shape. See AFC’s Maintenance, Fabrication and Storage Guidelines.

Panels must be cut dry using a diamond tipped or carbide saw blade. AFC recommends using its saw blade on all products. The feed and turn rate should be lowered to reduce heat and to create a cleaner straighter cut. See AFC’s Maintenance, Fabrication and Storage Guidelines.

The Natural product line does not require edge sealant. AFC Surface, AFC Core, and AFC Matte require edge sealant when cutting is performed on-site. All panels that are cut by AFC will come to the jobsite already sealed. For Minerit HD, see our sealing requirements. For AFC Rustic, all edges must be painted. AFC will paint all edges it fabricates. See AFC’s Maintenance, Fabrication and Storage Guidelines for information on AFC Rustic edge paint and sealing of AFC Surface, AFC Core, and AFC Matte.

AFC panels installed in exterior applications must have an air cavity behind the panel. This allows the panel to dry equally on each side after moisture exposure. See AFC’s Standard Installation Guidelines. For interior applications, the panels may be attached directly to the wall. See AFC’s Interior Installation Guidelines.

See AFC’s many sets of Standard Installation Details. Terminations into other products should have 3/8” openings with no caulking or sealant. Parapets should be capped off but leave 1” off the surface of the panel and 1” off the top of the panel for airflow. The base should also have a 1” opening for airflow.

The oversized holes allow for the panel to properly expand and contract during different environmental conditions without bowing or cracking. See AFC’s Standard Installation Guidelines for proper hole placement and sizing.

Yes. The installation is identical to the standard wall installation except the maximum on-center spacing is 16”.

See our Technical Bulletins for detailed visuals of every aspect of installation.